Discovering the Top 6 Printing Solutions for Your Professional and Business Projects

With hundreds of printing techniques, it can be tricky to choose the right one. Our guide explores six popular printing methods, each with its own strengths and quirks. This Blog explains how each method works and helps you pick the best one for your project. Whether you want to impress with your business cards or your colourful merchandise. Let's unlock the power of printing for your next project together!

Let’s look at the different types of printing

1. Digital Printing

Digital printing is a modern technique that replicates digital images onto a variety of surfaces, unlike traditional Printing methods that use manual labour and long production hours. Digital printing is quick and easy, Computer files are directly transferred to paper, cardstock, Fabric and other materials. Digital printing is perfect for small print runs as it is time-effective and can be done on an urgent basis. Stationeries such as Visiting cards, Letterheads, notebooks, Envelopes, posters, Flyers etc are done on digital printing.

Benefits of Digital Printing

Reduced Production Time

Digital printing eliminates the need for traditional setup processes, enabling quicker turnaround times than offset printing.

Pocket-Friendly for Short Runs

Digital printing is cost-effective for small print runs because there are no setup costs for plates or screens used in offset printing.

Variable Data Printing

Digital printing technology allows for the production of unique and customised prints, making it an ideal option for personalised marketing collateral.

Higher Resolution

Modern digital printers can produce high-resolution images and text, rivalling the quality of offset printing.

Printing on-demand

Digital printing allows for printing only the required quantity, reducing waste and storage costs.

Limitations of Digital printing

Limited Colour Matching

Achieving precise colour matching can be challenging in digital printing, especially when compared to offset printing methods.

Higher Cost per Unit for Large Runs

While digital printing is cost-effective for small print runs, it can become more expensive per unit for larger quantities compared to offset printing.

Restrictions on Print Size

Digital printers often have size limitations, restricting the maximum dimensions of printed materials compared to larger format offset printing presses.

Less Economical for Bulk Printing

For very large print runs, the cost-effectiveness of digital printing diminishes compared to offset printing, which may offer lower costs per unit.

2. Screen Printing

Screen printing is a very flexible printing method where the ink is pushed through a fine mesh screen onto materials like Paper, Fabric or Plastic. A stencil is produced on the screen by slicing off the portions not meant for printing. The desired image or design is then transferred to the substrate by using a squeegee to push ink through the stencil's open areas. Screen printing is widely used for clothing, posters, signage, and promotional products because of its brilliant colours, long-lasting nature, and versatility in printing on many surfaces. It is reasonably priced for medium to big print runs and provides exact details.

Benefits of Screen Printing

Vibrant and Long-lasting Prints

Screen printing yields vibrant colours and durable prints, ensuring longevity even after multiple washes or extended outdoor exposure.

Versatility

It can print on various surfaces, including fabric, paper, plastic, metal, and wood, making it suitable for diverse applications such as apparel, posters, signage, and promotional items.

Cost-effective for Medium to Large Runs

Screen printing becomes more cost-effective as the quantity of prints increases, making it ideal for medium to large print runs.

High-quality Detail

Screen printing offers excellent detail and precision, capturing intricate designs and fine lines with clarity.

Limitations of Screen Printing

Complex Setup Process

Setting up screens for each colour in the design can be time-consuming and require skilled labour, making it less suitable for short print runs or one-off projects.

Limited Colour Options

Each colour in a design requires a separate screen, limiting the number of colours that can be used in print and potentially increasing production costs.

Not Suitable for Complex Designs

Designs with intricate details or gradients may not reproduce well with screen printing, as it is better suited for bold, solid colours and simple shapes.

Ink Thickness

Screen printing can result in a thicker layer of ink compared to other printing methods, which may affect the texture of the printed surface, especially on fabrics.

Less Environmentally Friendly

The screen printing process involves using chemicals, such as emulsions and solvents, which can have environmental impacts if not handled and disposed of properly.

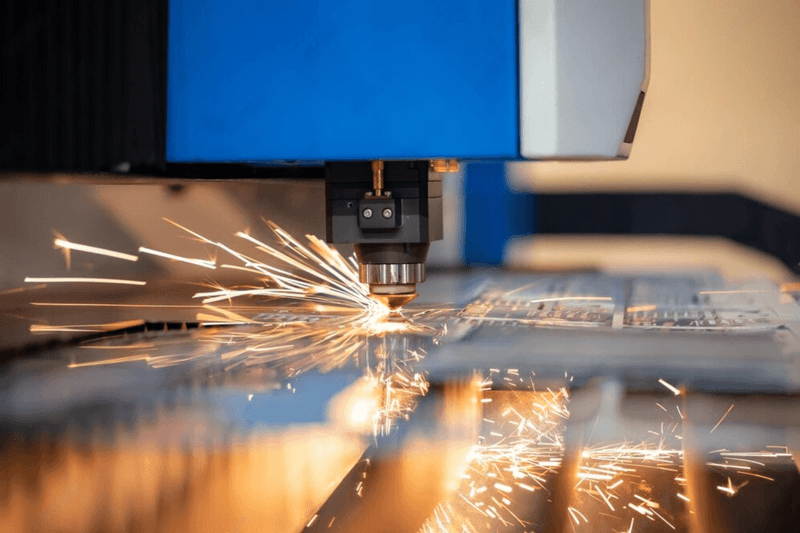

3. Laser Engraving

A Rapid and adaptable technology for permanently engraving designs, text, or images onto a variety of materials, such as wood, metal bottles, glass and plastic is called laser engraving. To create a required design on the material a focused beam of light usually from CO2 or fibre laser, is used to evaporate or destroy the material’s surface. Great precision is possible with laser engraving, enabling fine lines and detailed designs. Laser engraving is frequently used to personalise objects like awards and presents as well as in the manufacturing of jewellery. With less material waste, laser engraving produces results that are long-lasting and of excellent quality.

Benefits of Laser Engraving

Precision and Detail

Laser engraving offers exceptional precision, allowing for intricate designs, fine lines, and small text to be accurately reproduced on various materials.

Versatility

It can be used on a wide range of materials, including wood, metal, glass, plastic, leather, and acrylic, making it suitable for diverse applications in industries such as manufacturing, signage, jewellery, and personalization.

Permanent and Durable

Laser engraving creates permanent marks that are resistant to fading, scratching, and wear, ensuring long-lasting results without the need for additional coatings or treatments.

Non-contact Process

As a non-contact process, laser engraving minimizes the risk of damage to delicate materials and allows for engraving on curved or irregular surfaces.

High Efficiency

Laser engraving is a fast and efficient process, capable of producing high-quality results with minimal setup time and material waste.

Limitations of Laser Engraving

Material Limitations

While laser engraving is compatible with a wide range of materials, some materials, such as certain metals or reflective surfaces, may require specialised equipment or techniques for optimal results.

Cost of Equipment

The initial investment in laser engraving equipment can be substantial, particularly for high-powered lasers or systems with advanced features.

Depth Limitations

Laser engraving is typically limited to surface-level engraving, and achieving deeper cuts or engraving may require multiple passes or specialised equipment.

Complex Setup

Setting up laser engraving parameters, such as power, speed, and focus, requires technical expertise and experimentation to achieve the desired results, especially for complex designs or materials.

Safety Considerations

Laser engraving involves the use of high-powered lasers, which can pose safety risks if not operated and maintained properly. Protective measures, such as safety goggles and ventilation systems, are essential to prevent accidents and exposure to hazardous fumes.

4. UV Printing

Ultraviolet (UV) Printing is a modern printing technology. In this technique, ultra-violet (UV) light is used to rapidly cure or dry the ink as it is applied to the printing surface. In this process UV sensitive ink is applied on materials such as paper and any other different materials and then the Printing area is exposed to the UV lights which instantly solidify the colour and give a sharp finish, this results in fine details, bright colours and long-lasting polish.

Benefits of UV Printing

Vibrant and Durable Prints

UV printing produces vibrant colours and sharp details with a durable finish, resistant to scratching, fading, and moisture.

Fast Drying Time

UV ink instantly cures upon exposure to UV light, resulting in rapid production speeds and reduced turnaround times compared to traditional printing methods.

Versatility

UV printing can be used on a wide range of substrates, including paper, plastic, glass, metal, and wood, allowing for diverse applications across various industries.

Environmentally Friendly

UV printing emits minimal volatile organic compounds (VOCs) and produces less waste, making it a more environmentally friendly option compared to solvent-based printing.

Enhanced Print Quality

UV printing enables the printing of fine details, textures, and special effects, such as embossing or varnishing, for added visual impact and tactile appeal.

Limitations of UV Printing

Higher Initial Investment

The equipment and technology required for UV printing can be more expensive compared to traditional printing methods, making it a significant investment for printing businesses.

Limited Substrate Compatibility

While UV printing can be used on a wide range of materials, some substrates may require pre-treatment or may not be suitable for UV curing, limiting the versatility of the process.

Potential for Ink Adhesion Issues

Certain substrates, such as flexible plastics or heavily textured surfaces, may pose challenges for ink adhesion during UV printing, requiring additional pre-treatment or testing to ensure optimal results.

Safety Considerations

UV printing involves the use of UV light, which can pose safety risks if not handled properly. Protective measures, such as UV-blocking glasses and proper ventilation, are essential to prevent exposure to UV radiation and fumes from the curing process.

Limited Colour Matching

Achieving precise colour matching with UV printing can be challenging, especially when compared to offset printing methods, due to differences in ink properties and curing processes.

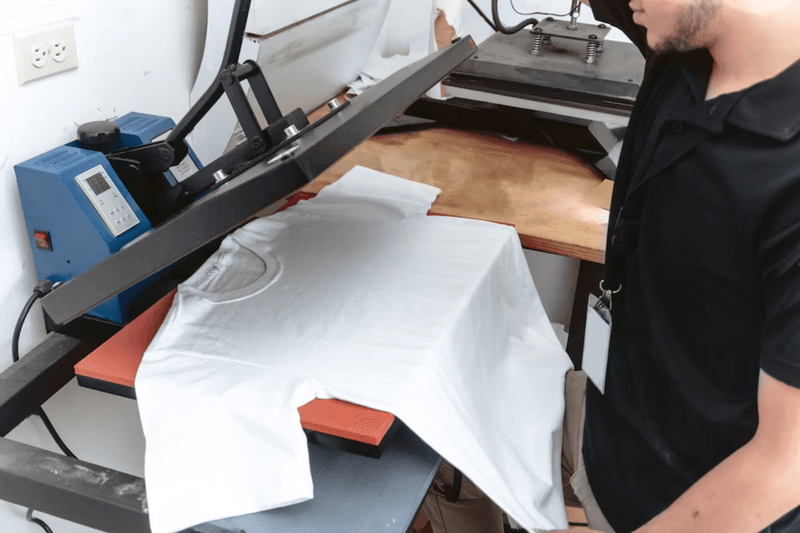

5. Fusing

Fusing is also known as Heat Printing where Heat and pressure are used in the printing process, to transfer designs onto materials. Using sublimation inks or toner, the pattern is printed using this technique onto a specific transfer paper. The paper is then placed on the material such as ceramics or fabric and heated at a high temperature while under pressure using a heat press machine. The ink or toner vaporizes and absorbs the material's surface due to the heat, forming a long-lasting connection. Custom clothing, promotional products, and personalized presents with eye-catching, long-lasting designs are frequently made utilizing fuse printing.

Benefits of Fusing

Versatility

Fusing printing can be used on a wide range of materials, including fabrics like polyester cotton and ceramics offering versatility in creating customised items.

Vibrant and Long-lasting Designs

The heat and pressure involved in fusing printing ensure vibrant colours and durable prints that resist fading, cracking, and peeling, providing a professional finish.

Customisation

It allows for high-quality, full-colour printing of intricate designs, logos, and photographs onto various products, making it ideal for personalised apparel, promotional items, and gifts.

Fast Production

Fusing printing offers quick turnaround times, making it suitable for on-demand printing and small to medium print runs, reducing lead times and inventory costs.

Ease of Use

With modern heat press machines and digital printing technology, fusing printing is relatively easy to set up and operate, requiring minimal personnel training.

Limitations of Fusing

Limited to Light-Coloured Fabrics

Fusing printing works best on light-coloured fabrics, as the printing process relies on the dye sublimation or toner transfer method, which may not be as effective on dark backgrounds.

Preparation Requirements

Proper preparation of materials, such as pre-treating fabrics or using specially coated substrates, may be necessary to achieve optimal results, adding to production time and costs.

Heat Press Equipment Needed

Fusing printing requires the use of heat press equipment, which can be expensive to purchase and maintain, especially for businesses with high-volume printing needs.

Not Suitable for All Materials

While versatile, fusing printing may not adhere well to certain materials with textured or uneven surfaces, limiting its applicability to smooth, flat substrates. Fusing printing type is suitable for materials or products made of Plastic.

Limited Detail and Resolution

Compared to some other printing methods, fusing printing may have limitations in reproducing fine details and intricate designs, especially on textured fabrics or surfaces.

6. Sublimation

Sublimation printing is a digital printing process in which sublimation inks are used to transfer graphics onto a particular kind of paper. Afterwards, heat and pressure are used to transfer the printed design from the paper onto a substrate, such as polyester fabric or coated materials like metal or ceramic. The sublimation inks are heated to a high temperature during the transfer process, which causes them to transform into a gas and pierce the substrate's surface. The ink solidifies and becomes permanently ingrained in the material as it cools, producing prints that are vivid, strong, and long-lasting with outstanding colour retention and detail.

Benefits of Sublimation

Vibrant and Long-lasting Prints

Sublimation printing produces vibrant colours and sharp details that are embedded within the substrate, resulting in durable prints resistant to fading, cracking, and peeling.

Versatility

It can be used on a variety of substrates, including polyester fabrics, ceramics, metals, and certain plastics, offering versatility in creating customised products such as apparel, mugs, signage, and promotional items.

Full-Colour Printing

Sublimation printing allows for high-quality, full-colour printing of intricate designs, photographs, and logos onto various surfaces, providing endless possibilities for customisation.

Soft-touch Finish

Prints created through sublimation printing have a soft-touch finish and remain breathable on fabrics, making them comfortable to wear and ideal for sportswear and apparel.

Environmental Friendliness

Sublimation printing is considered environmentally friendly as it produces minimal waste, with any unused ink remaining on the transfer paper rather than being wasted.

Limitation of Sublimation

Limited to Polyester and Coated Surfaces

Sublimation printing is most effective on polyester fabrics and materials with a special polymer coating, restricting its applicability to specific substrates.

Preparation Requirements

Proper preparation of materials, including pre-treatment of fabrics or using specially coated substrates, may be necessary to achieve optimal results, adding to production time and costs.

Heat Press Equipment Needed

Sublimation printing requires the use of heat press equipment, which can be expensive to purchase and maintain, especially for businesses with high-volume printing needs.

Not Suitable for Dark-Coloured Fabrics

Sublimation printing works best on light-coloured fabrics, as the printing process relies on the sublimation of dyes, which may not be as effective on dark backgrounds.

Limited Detail on Textured Surfaces

Sublimation printing may have limitations in reproducing fine details and intricate designs on textured or uneven surfaces, affecting the overall print quality and clarity.

Conclusion

The diverse world of printing offers a range of techniques, from the rapid efficiency of digital printing to the vibrant colours of screen printing, the precision of laser engraving, and the versatility of UV printing, fusing, and sublimation. Whether you're a professional or a consumer, understanding these methods helps in making informed decisions for projects. Each technique has its benefits and limitations, influencing factors include production needs, budget, and desired quality. For personalised printing solutions tailored to your needs, PrintStop offers customised products adorned with logos, names, and bespoke designs, ensuring top-notch quality and customer satisfaction in every print. By harnessing the power of printing, one can effectively communicate, create visually appealing designs, and bring ideas to life.